Manufacturing ERP

Benefit from greater system agility with faster response times to shifting market conditions and order demands.

Optimize manufacturing performance

Priority Manufacturing ERP software provides a 360-degree, real-time view of production facility performance, tracking, and enhancement capabilities. Using a wide range of reports and analytics to help optimize operations, improve visibility and remove inefficiencies, Priority’s Manufacturing ERP software’s automated processes empower seamless and immediate synchronization between units, preventing delays and errors, from engineering all the way to production.

Unlocking your company's true value!

When it comes to manufacturing software, Priority understands your business needs. If you’re a manufacturer, no matter what your end-product or service, chances are you have a demanding customer at the end of the assembly line. It’s here that manufacturing execution system software has the potential to boost your business.

Manufacturing ERP Key Features

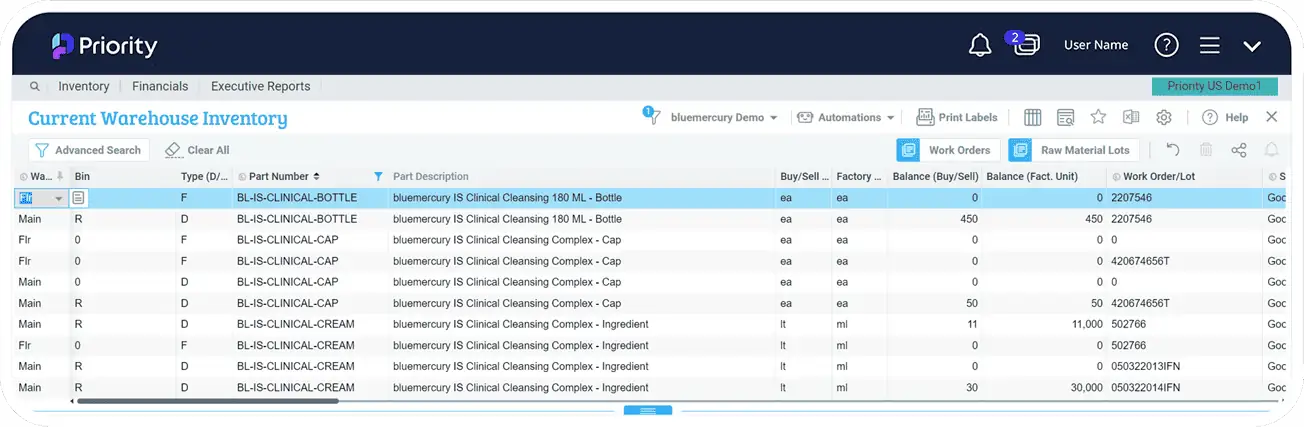

Inventory Control

Inventory control is often the cornerstone of any successful manufacturing operation. It’s what drives your shop floor, supports materials handling and it’s what helps drive your revenues. Viable inventory control means reducing inventory costs and enhancing tracking and traceability, maintaining tight control on inventory replenishment.

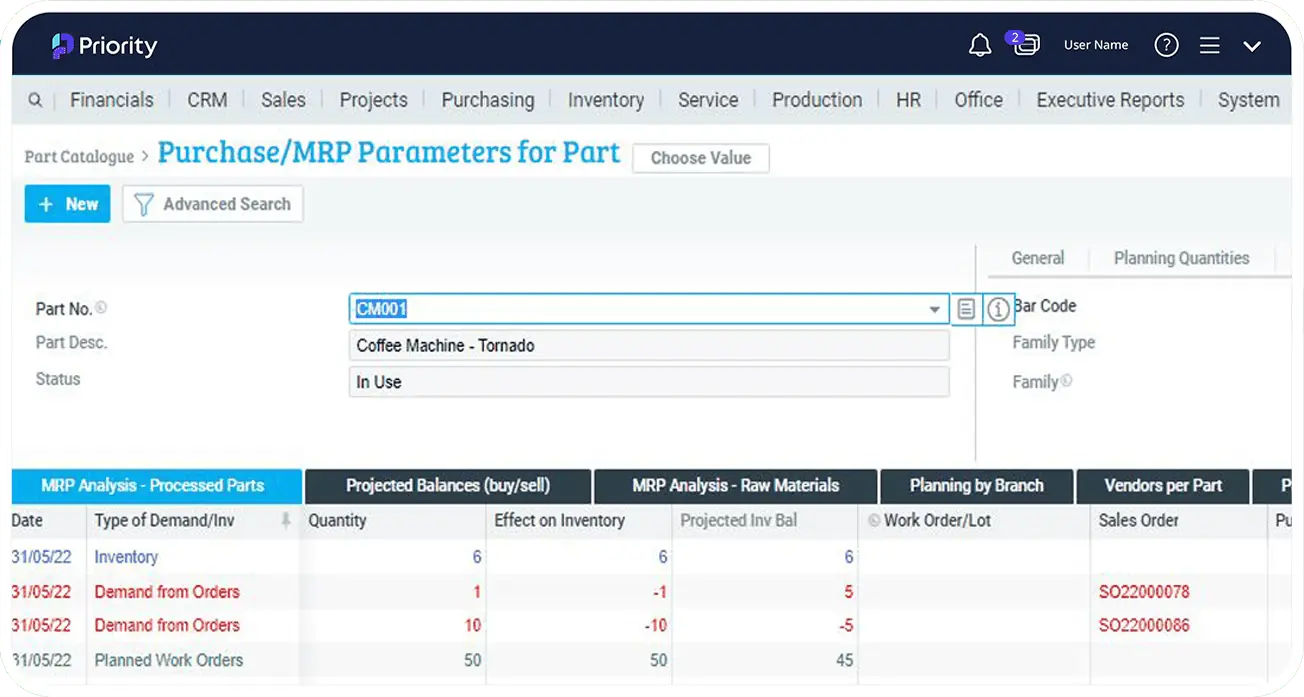

Material Requirements Planning

Material Requirements Planning (MRP) is a production planning, scheduling and inventory control system used to manage manufacturing processes. Composed of these and other linked functions and all related support systems, MRP determines material requirements based on sales orders, open work orders or frequency of need.

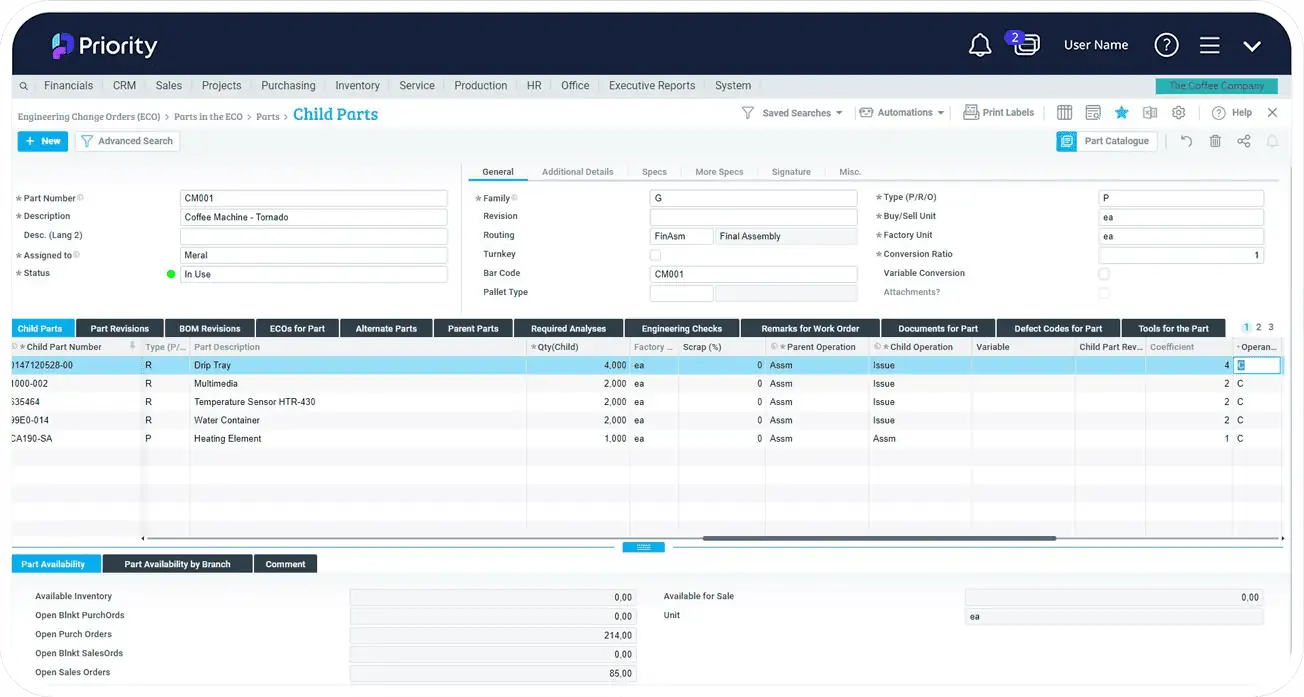

Product Data Management

PDM effectively plans and coordinates an organization’s transactional operations, including sales order management, purchasing, cost accounting and logistics. Part of the larger concept, Product Lifecycle Management(PLM), PDM maintains manufacturing part numbers, bill of materials (BOM) and integrates with Product Change Control (PCC).

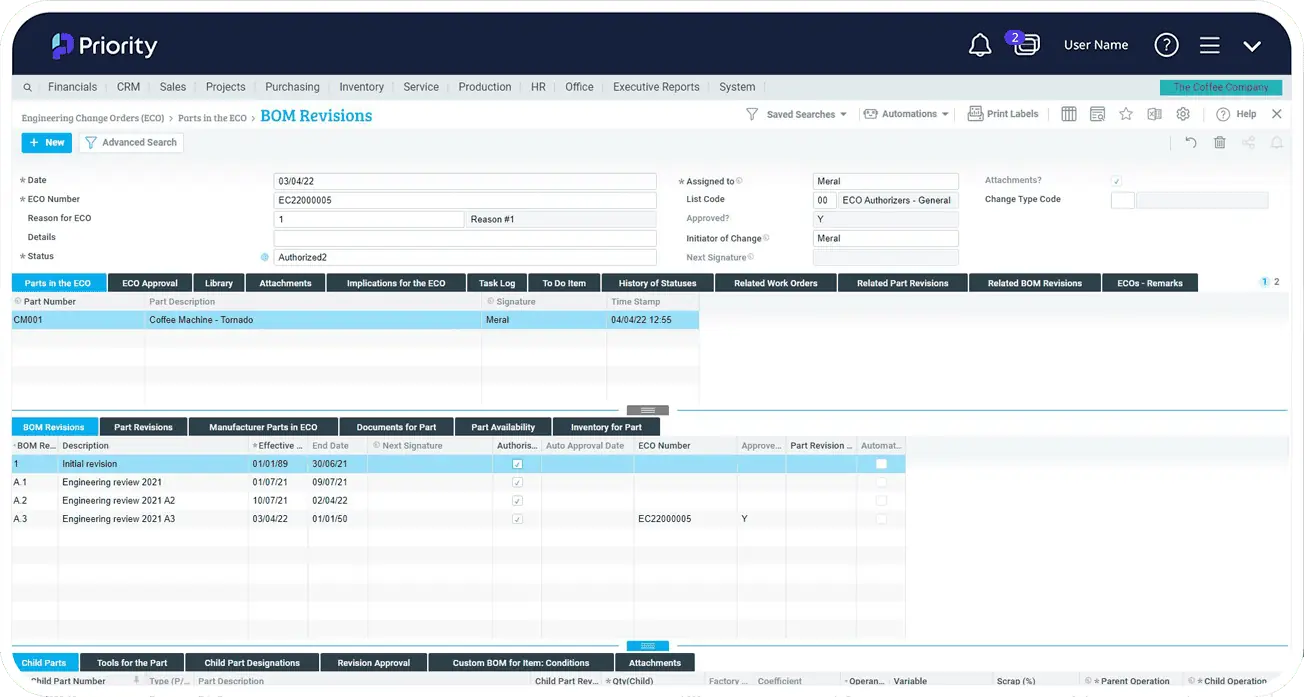

ECO Management and Revision Control

Manufacturers must respond quickly with engineering changes in order to maintain and increase market share. Effective ECO management combined with revision control provides immediate response to market demand, governmental requirements, safety issues, service requirements or functional and competitive needs in the manufacturing process, including optimizing, organizing and tracking their approval process.

Multi-Division and Multi-Site Planning

Powerful functionality used to support distribution organizations with multiple distribution centers and/or multiple sites around the world. Priority serves multiple divisions at any given company, with each site maintaining its dedicated inventory and/or distribution, while planning and purchasing may be handled multi-site or separately. Process are easily adjustable for multiple production control methods used in discrete, repetitive and mixed-mode manufacturing.

Manufacturing Execution

Comprehensive control system for managing and monitoring work-in-process on the shop floor, a Manufacturing Execution System (MES) keeps track of all manufacturing information in real time, receiving up-to-the-minute data from robots, machine monitors and employees. Essential in tracking operations and production progress, quality control, rework and scrap ratios, while supporting data collection via bar code or RFID.

Benefits.

Increase efficiency

Your manufacturing process is the hub of your entire operation. Reduce costs and increase your bottom line with improved inventory management, boosted employee productivity, enhance workflows and processes and increase overall process control with real-time views of your business.

Eliminate unnecessary downtime

Manufacturers know that downtime is a costly business and reducing or eliminating unnecessary downtime, especially supply chain disruption, is critical to any manufacturing operation. Priority lets you effectively gain control and insight into your supply chain and minimize your risk of downtime.

Enhance production and performance

Priority helps you accelerate your entire manufacturing operations – from the production planning phase through to scheduling, execution and real-time analysis. Achieve measurable results on the shop floor with the tools you need to keep up with market requirements, make changes in real-time and yield high quality results on every end product.

Improve supply chain visibility

Priority raises the bar on comparable ERP solutions for its unique ability to increase the quality and visibility of information that today’s manufacturers need to make the best possible decisions to drive their businesses forward. From strategy to operations, finance to employees, Priority’s manufacturing solution controls every step of the way – from supplier raw materials to packaged products en route to end customers.

Multiple tools in a single system

All the tools you need to manage and control the entire manufacturing process, all with a single database that eliminates costly third-party integration. Supported by a single development team, your organization will benefit from lower overall cost of investment, decreased maintenance costs and faster ROI.