Electronics ERP

Grow your electronics business from development and engineering to fully compliant end-products delivered to your customer’s door, on time and on budget.

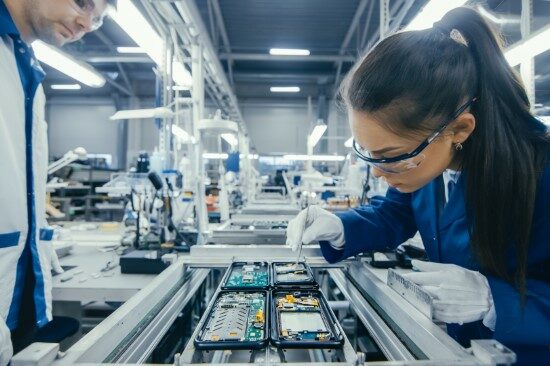

Floor-to-door production management

Priority cloud ERP for electronics manufacturers is a fully integrated, end-to-end management solution leveraging real-time visibility into the supply chain, streamlining business processes, and automating the entire electronics manufacturing process. From production planning and manufacturing execution to supply chain management, finance and accounting, by enabling companies to make informed, data-driven decisions and drive efficiency, Priority ERP helps reduce costs and increase profitability, allowing electronics manufacturers to get their products out to the market faster.

Priority Tech: ERP Solutions for the Electronics Manufacturing Industry!

Priority ERP software helps streamline your business processes and reduce internal errors by automating the entire electronics manufacturing process. Automated operations lead to increased productivity, enhanced customer service and a high return on investment. This is Priority Tech.

Comprehensive electronics production management and control – from the shop floor to the end-customer. Designed to serve SMEs, Priority Tech effectively supports the entire supply chain. This means smart and reliable tools to grow your business, including superior supply chain management with integrated views and full product line visibility from engineering to production and real-time alerts at every stage in the process.

Priority Tech supports the next revolution in electronics manufacturing and manufacturing management, including IoT and Industry 4.0, with a dedicated REST API. This is achieved with our mobile app development tools where users can build applications in Priority without writing a single line of code!

Electronics ERP Key Features

Material Requirements Planning (MRP)

Plan your purchasing and production processes accurately across all your facilities based on system recommendations to optimize your stock levels, meet time-to-market and increase customer satisfaction. Get automatic calculation of required quantities based on various data sources, such as forecasts, orders, safety stock, current stock, lead time, and WIP.

Inventory & Supply Chain Management

Effectively manage and control your entire supply chain with automated processes, including shop floor control, batch control/tracking and multiple distribution channels, complete visibility of your raw materials and inventory, and managing perishable raw materials and end-products with limited shelf-life. Priority ERP includes advanced tracking and traceability tools to ensure your products are safely stored and transported at the correct temperatures in controlled and compliant environments.

ECO Management & Revision Control

Priority’s ECO management, combined with tight revision control, delivers an immediate response to market demands, government requirements, safety issues, and service, functional and competitive requirements in your manufacturing process. Our robust and reliable ECO management tools optimize, organize, and track your complete revision control and approval process.

Engineering Change Orders

Manage engineering changes of parts and BOMs. Easily document change details, dates, parts that have been affected, and more. The ECO module allows you to integrate part and BOM revisions to engineering changes, while Priority’s system tracks revisions affected by the change, as well as work orders opened in accordance with the revisions.

Finance & Accounting

Gain and maintain control of your manufacturing project budget with advanced tools, including accounts receivable/accounts payable, time & attendance, and comprehensive cost management, including job cost, and standard/actual cost, end-to-end budget management, profit centers, and multi-currency and multi-company capabilities.

Benefits.

Mobile app development tools

Dedicated REST API supports the next revolution in electronics manufacturing and manufacturing management, including IoT and Industry 4.0. With our mobile app development tools, users can build apps in Priority without writing a single line of code!

Increase efficiency

Reduce your manufacturing costs and increase your bottom line with superior inventory management, boosted employee productivity and faster workflows and processes.

Enhance performance

Accelerate your entire manufacturing process, from production planning through to scheduling, execution and real-time analysis and profit from quality results on every finished product.

Multiple tools in a single system

Priority Tech gives you end-to-end control, all with a single database, eliminating costly third-party integration.